Housings / Assembly

By way of additionally qualified manufacturers specializing in housings / plastic injection moulding and assembly, our product and service catalogue offers excellent possibilities far beyond a supply of standard components:

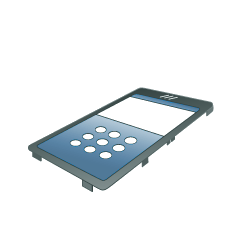

Customized equipment housings and backlight housings for LCM/LCD modules with advanced features and elements such as snap hooks for easy mounting of display modules in the devices or attachment of further components – development of customer-specific components and modules, ranging to customized assembly groups ready for further processing form part of our daily activities.

Advantages:

- Customization of standard products

- Components developed entirely according to customer specifications

- Development of complete, customized modules (e.g. display with touchscreen function including backlight housing + PCB)

- Tool manufacture + production of plastic components and housings

As concerns the manufacture of tools and prototypes, our agreements with manufacturers guarantee no additional costs of corrective action or modifications desired during the development process, beyond the scope of the approved tooling costs.

We provide you here with comprehensive project support from planning and development through manufacture of prototypes right up to serial production.

Defined project sequence for customer-specific developments:

- Product planning and development

- Drawing approval

- Tool manufacture

- Tool approval

- Prototype manufacture

- Prototype approval

- Serial production

All data and tools are provided to you on completion of the project. In this process, we guarantee customer and application security, consistently high product quality and reliable delivery under the best possible terms.